UBC’s Bioproducts Institute (BPI) is a partner of choice for organizations wanting to create sustainable products and processes in industries ranging from packaging to health care.

In January 2023, BPI launched Advancing Technology Readiness (ATR), an industry-driven program that supports the development of investment-attractive biobased innovations.

This stage-gate approach de-risks technology for manufacturing, and establishes an economic and environmental assessment for commercialization.

Bridging the gap from idea to technology

Whether you are a clean tech startup or a multinational organization, it’s extremely challenging to optimize a new product or process to meet technical specs, sustainability goals and economic constraints without having access to applied research expertise or specialized equipment.

Partnering with BPI can help organizations connect to the talent and infrastructure needed to develop ideas into marketable products or processes.

“Historically, there’s been a big gap between research in the lab and what industry is ready to take up and invest in,” says Richard Sones, Director of Partner Innovations.

“At BPI, we’re supporting the technology side of the commercialization equation. Through the ATR program, we can support a technology’s readiness level on multiple levels and then advance it to the point where it can be launched.”

From technology to investment ready

The ATR framework consists of five stages and four decision-making gates to move a technology from innovation analysis through to proof of concept and ultimately being ready to launch as an investment-ready venture.

The process is overseen by an advisory board, an industrial/commercial technical team and a project-specific advisory team, with defined services and deliverables at each stage.

“Each project is unique and at different readiness levels,” says Sones.

“We bring the specialized expertise and resources needed to advance a technology through a defined development process that can include addressing specific technological risks like energy input, resolving scalability issues or establishing the intellectual property/ freedom to operate.”

Bioproducts offer sustainable solutions with countless applications

BPI researchers are collaborating with industry and government partners on projects that fall into three broad categories:

- The sustainable built environment: Using forest-based materials in structural and functional applications, including heat and sound insulation, energy management and textiles.

- Green consumer products that use bioproducts to replace fossil-fuel-based plastics.

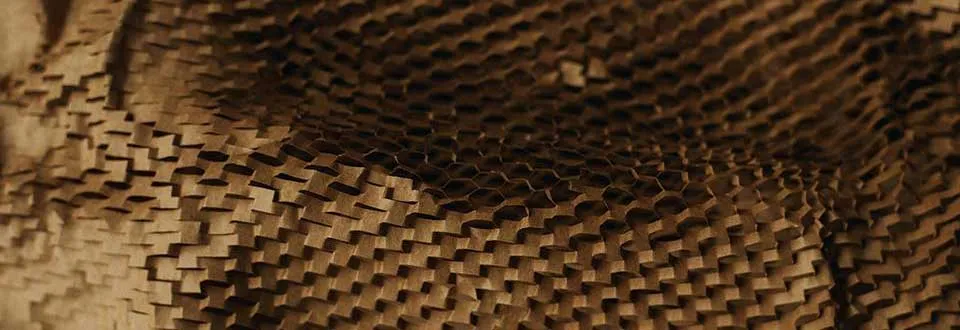

- Renewable packaging, ranging from single-use food packaging to protective cushioning for high value electronics.

BPI recently published a whitepaper with Apple to explore how fibre-based materials in cushioning packaging can help remove plastic from packaging materials. The paper explores both material functionality and the impacts on manufacturing and the marketing value chain.

Team members are currently setting up a pilot plant to increase production capacity.

Another project is advancing an ultralight weight material made from hemp fibres that could have applications in outerwear or providing insulation for transporting pharmaceuticals that need to be maintained at specific temperatures.

A partner for growth

“The challenge with this kind of innovation development is that you can’t just develop it in your garage,” says Sones. “You need expertise and specialized infrastructure, and that’s where we come in."

"Here at UBC, we can tap into incredible expertise on virtually any technical topic to help solve problems perhaps more quickly and cost-effectively than could be done otherwise.”

“It’s more than climate change,” says Sones. “It’s about sustainability, about making sure our precursors/ building-blocks and processes to create products are sustainable, that the products we create are truly recyclable and that the embedded carbon comes from non-new-fossil sources. The answers are there, in nature.”