Smarter sensors developed at UBC deliver core insights

Traditional approaches to mineral exploration can be expensive, time-consuming and imprecise, relying on labour-intensive geological interpretation and slow laboratory analyses. UBC Professor of Mining Engineering Bern Klein is advancing sensor technologies to identify critical minerals in drill core samples more quickly and accurately. This innovation could provide greater certainty for companies during feasibility planning while also accelerating the development process.

Sensor technologies improve mining practices

Sensors have been used in mineral processing plants for decades and are increasingly found on excavator shovels and conveyor belts to detect metal content upstream of the processing circuit. MineSense, a company co-founded by Klein, has developed X-ray fluorescence (XRF) sensors that are attached to shovels to determine metal content in real time at the point of excavation. This technology provides mine operators with the data they need to make immediate decisions about whether the material should be processed or discarded.

“Mines that use this system are recovering about an additional 10 per cent of material,” says Klein. “That’s impressive. However, while the XRF technology is great for base metals like copper, it is not as useful for other metals – and that’s why we are developing new sensor technologies.”

A laser-focused approach

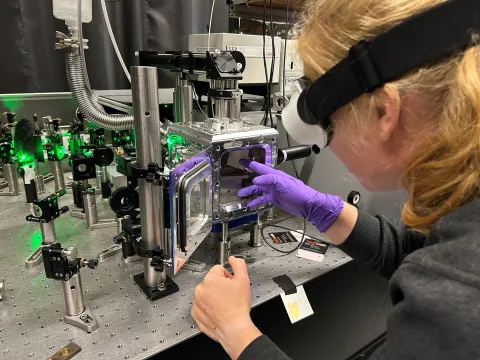

Klein and his colleague David Jones, a physics professor at UBC, are advancing new sensor technologies, including laser ablation dual-comb spectroscopy (LA-DCS). LA-DCS works by firing a laser pulse at a sample to vaporize a tiny amount of material. The emitted light is then analyzed to precisely identify the sample’s chemical composition, without requiring labour-intensive sample preparation or chemical reagents.

“Scanning core samples with LA-DCS generates a consistent high-resolution digital record of the sample’s chemical composition,” explains Klein. “The sensors can generate a huge amount of data that we just couldn’t access before.”

The potential benefits of this technology are significant. By providing high-resolution, objective digital records of drill core samples, the sensors eliminate much of the subjectivity and variability inherent in traditional geological logging.

At the exploration stage, companies will have a much more detailed and accurate understanding of both the location of metal content as well as the variation in mineral composition. This data can be used to inform mine planning and downstream mineral separation processes.

Once proof of concept is demonstrated using drill core samples, Klein and his team intend to look at how these technologies can be integrated at the excavator interface or along conveyor belts at mill sites. Currently supported by funding from the Canada Foundation for Innovation and the NSERC Alliance, the group expects to have pilot applications and potentially in-the-field operations within four years.

A critical opportunity for critical minerals

Canada is rich in mineral wealth, including deposits of the critical minerals that are essential for clean energy applications and advanced manufacturing. However, many deposits currently fall below economic viability thresholds.

“If you look at the critical minerals, like rare earth elements and lithium, we have marginal deposits,” says Klein. “However, we believe that by applying these sensing technologies we can transform sub-economic mineral deposits into economically viable projects.”

If all goes to plan, this will be yet one more example of how sensor technologies are making mining operations more sustainable and efficient.

UBC Applied Science is a partner in innovation

Klein’s project is just one of many being undertaken by UBC’s leading researchers, working in collaboration with industry partners to advance innovative and scalable solutions that meet the growing demand for sustainable mining exploration, development and operations.